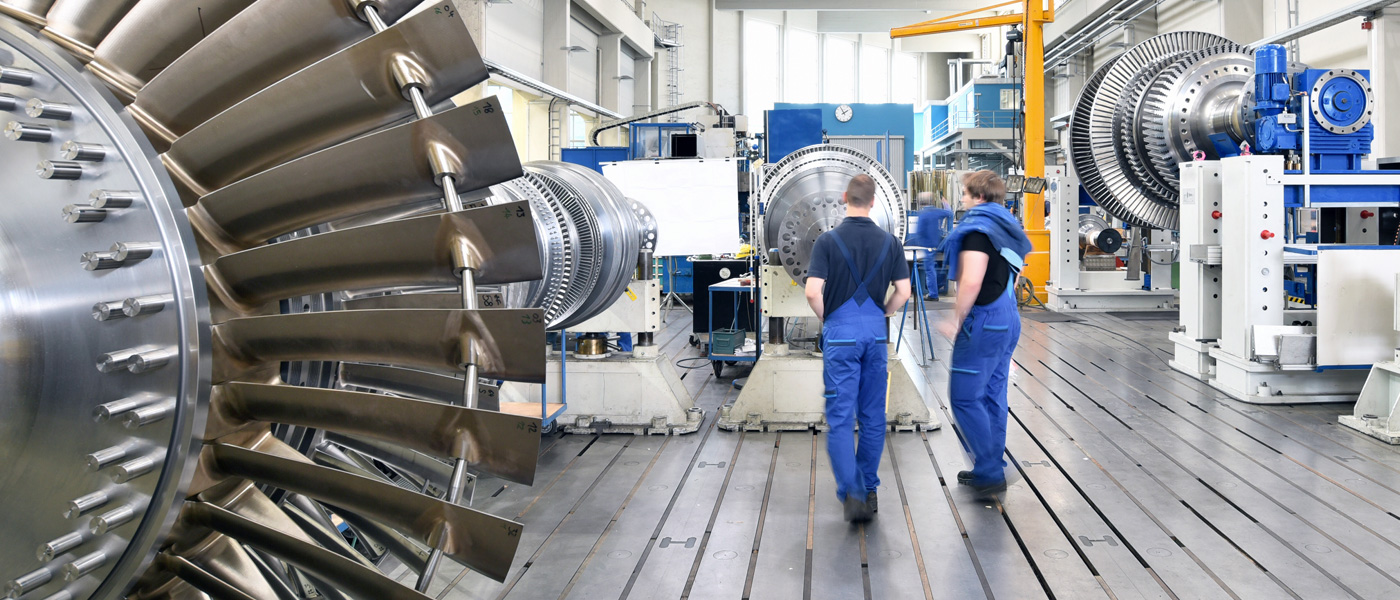

VON DER ENTWICKLUNG

BIS ZUR FERTIGEN MASCHINE

//

Präzise, passgenau, effizient! HSK Anlagen- und Tafelscheren werden konsequent auf die individuellen Anforderungen unserer Kunden ausgerichtet. Jede Schere wird sorgfältig konzipiert, konstruiert und gefertigt. Dabei vereinen unsere Produkte die jahrzehntelange Erfahrung und unser einzigartiges Know-how mit energieeffizienter und innovativer Trenntechnologie.

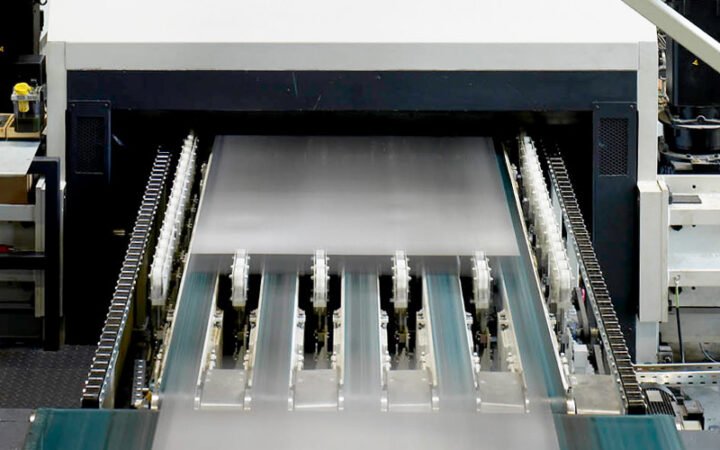

ANLAGENSCHEREN

Kundenspezifische Scheren für automatische Produktionslinien.

Unsere qualitativ sehr hochwertigen Scheren werden häufig mit vor- und nachgelagerten Maschinen zu einer automatischen Produktionsstraße verkettet. Die Maschinen werden hierfür in Abstimmung mit dem Kunden konstruiert und gefertigt.

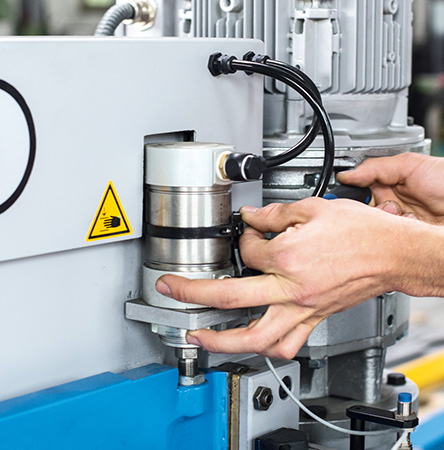

Auch der motorische Antrieb der Schere wird nach Kundenanforderung ausgelegt und je nach Bedarf ein Antrieb mittels AC-Getriebebremsmotor, mittels Servogetriebemotor oder mittels Schwungrad und pneumatisch oder hydraulisch betätigter Kupplungs-Brems-Kombination realisiert.

TAFELSCHEREN

Individuelle, alleinstehende Scheren für unterschiedlichste Materialien.

HSK-Tafelscheren aus unserem Haus sind alleinstehende, motorisch betriebene Maschinen mit elektrischer Steuerung, zumeist zum Zerteilen oder Besäumen von Blechtafeln.

Es können jedoch auch beliebig andere Werkstoffe wie z. B. Kunststoffe, CFK/GFK, Vlies, Schaumstoffe oder Edelmetalle geschnitten werden, hauptsächlich in Form von Tafeln, jedoch auch in Form von umgeformten Werkstücken wie Tiefziehteile und Profilbleche oder direkt vom Coil.

ENERGIEEFFIZIENTE TECHNIK

Schneiden mit höchster Präzision bei minimalem Ernergieverbrauch.

Motorisch betriebene Exzenterscheren von HSK zeichen sich neben der hohen Präzision, Schnittgeschwindigkeit und Robustheit inbesondere durch eine sehr hohe Energeieffizienz und Umweltverträglichkeit aus.

Die Nachteile hydraulisch betriebener Scheren wie der großen Verlustwärme und dem Einsatz großer Mengen Hydrauliköl bei gleichzeitig geringer Hubzahl entfallen. Stattdessen wird der motorisch betrieben Antrieb der HSK-Schere individuell für die jeweilige Aufgabenstellung des Kunden konzipiert und so zwischen den möglichen Varianten AC-Getriebemotor, Servogetriebemotor und Kupplungsantrieb ausgewählt.

HOCHWERTIGE LÖSUNGEN

FÜR NAHEZU ALLE ANFORDERUNGEN

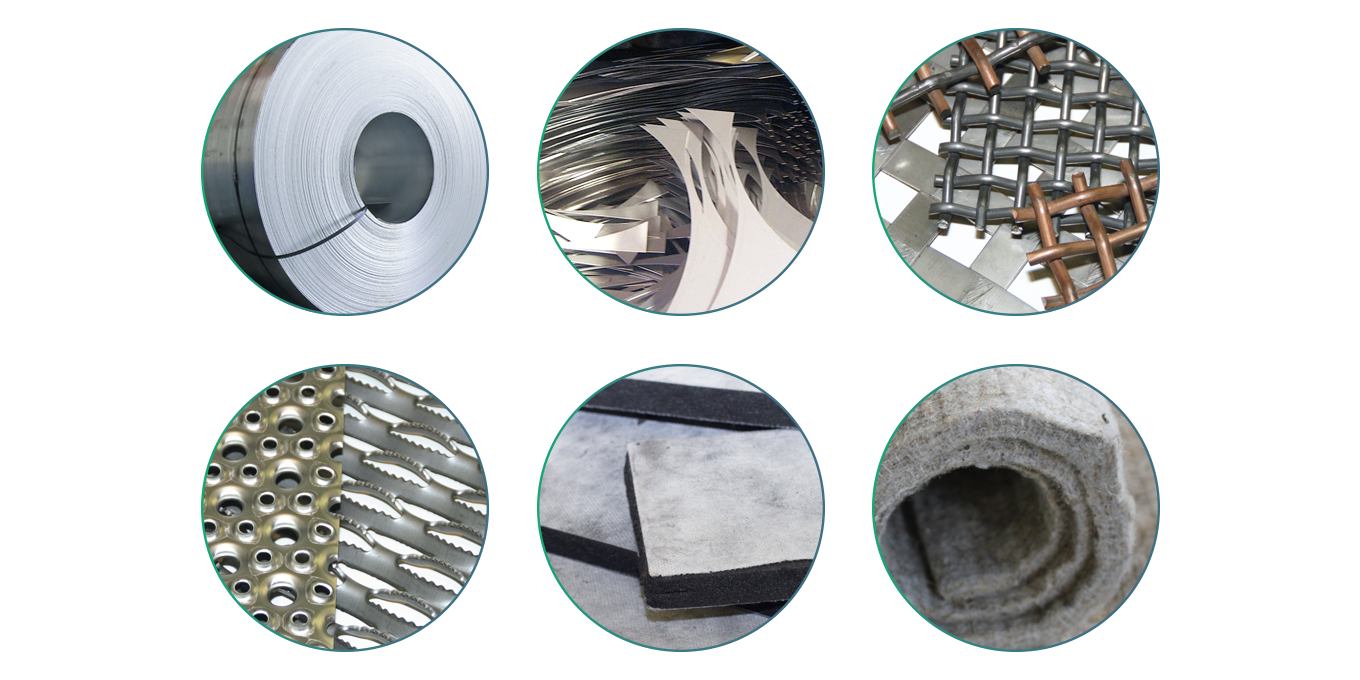

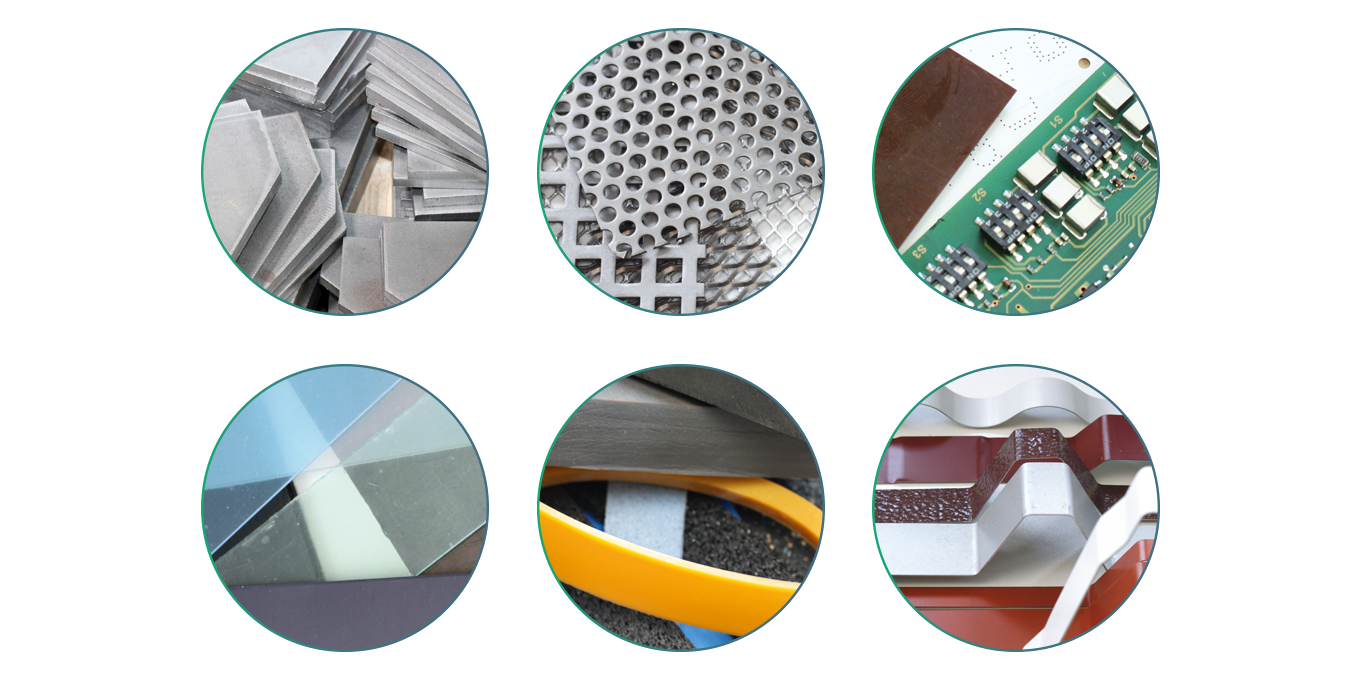

Materialien

Der perfekte Schnitt für zahlreiche Materialien.

HSK-Anlagenscheren: Blechband / Stanzgitter / Blechtafeln / Elektroblech / Blechprofilband / Genadeltes Alu / Kunststoffbahnen / Kohlefiltermatten / Vliesbahnen / Schaumstoffbahnen uvm.

HSK-Tafelscheren: Blechtafeln / Schweißknotenbleche / Lochbleche / Gummi / Streckmetall / Kupferkathoden / Edelmetalle / Leiterplatten / Kunststoff / Schaumstoff / Wellpappe / Trapezblech uvm.

UNSER SERVICE

RUNDUM SORGLOS

//

HSK ist Ihr verlässlicher Partner für Anlagen- und Tafelscheren. Rund um unsere HSK-Maschinen bieten wir Ihnen umfangreiche Dienstleistungen und einen kompetenten Service, wie z. B. Wartung, Optimierungen oder Rundumerneuerung.

SERVICE VOR ORT

Gerne führen wir bei Ihnen im Haus die Wartung Ihrer HSK-Maschinen durch und kümmern uns um den Austausch der Verschleißteile.

GENERALÜBERHOLUNGEN

Retrofit – aus Alt mach Neu!

Bei einer Generalüberholung wird die HSK-Exzenterschere komplett zerlegt und rundumerneuert.

MESSERSERVICE

Wir helfen Ihnen gerne beim Nachschleifen oder Umschleifen von HSK-Maschinenmessern oder Fremdfabrikaten.

LOHNFERTIGUNG

Die Hauptkompetenz unserer Lohnfertigung besteht in der flexiblen Fertigung verschiedener Bauteile in kleinen Losgrößen.

REGIONAL VERANKERT

WELTWEIT IM EINSATZ

//

3864+

Realisierte Scheren

2680+

Zufriedene Kunden

108

Jahre Erfahrung

116

kWp installierte PV-Anlage

Die Firma HSK ist seit ihrer Gründung in Kirchheim unter Teck am Fuße der Schwäbischen Alb in Baden-Württemberg ansässig. Wir verstehen uns als typisch schwäbisches Familienunternehmen, welches solide und bodenständig wirtschaftet und kundenspezifische Maschinen höchster Qualität anfertigt.

Karl Huttenlocher gründete die mechanische Werkstatt im Jahr 1915 in Kirchheim unter Teck. Stolz blicken wir auf eine inzwischen 100 Jahre alte Firmengeschichte zurück und darauf, dass die Firma nach wie vor ein echtes generationenübergreifendes Familienunternehmen ist.

Auch sind wir stolz darauf, dass trotz unserer überschaubaren Betriebsgröße nahezu sämtliche namhaften Automobilhersteller und -zulieferer mit unseren Maschinen ihre Bleche rund um die Uhr zerteilen.

Zudem werden wir bei jeder Waschmaschine, jedem Schaltschrank, jedem Transformator, jeder Kauleiste in der Zahnmedizintechnik, jedem Maschinenschild und vielen weiteren Endprodukten an unsere Kunden und den dort eingesetzten Scheren aus unserem Haus mit Begeisterung erinnert.

Firmengeschichte

1915

Karl Huttenlocher gründet eine mechanische Werkstatt in der Röhmmühle in der Gaisgasse in Kirchheim/Teck.

1936

Fertigung der ersten mechanischen Tafelschere.

1994

Fertigung der ersten Tafelschere zum Schneiden von Well- und Trapezblechen.

1998

Fertigung der ersten mechanischen Tafelschere mit Tandemantrieb zum Schneiden von Blechen bis 15 mm.

2003

Fertigung der ersten Doppelschere mit Oberantrieb zum Schneiden von Abfallblechen mit garantierter Maximallänge.

2008

Installation der ersten PV-Anlage auf dem Hallendach mit bereits 30 kWp.

2009

Fertigung der ersten Querteilschere in Langhubkonstruktion mit Servo-Antrieb als Schwenkschere.

2013

Fertigung der ersten Schopfschere in C-Bügelkonstruktion.

2014

Fertigung der ersten Doppelschnittschere mit einem gemeinsamen Messerbalken zur Stanzgitterentsorgung.

2014

Fertigung der ersten Profilschere zum Zerteilen hoher Dachprofile TP 100/275 und TP 135/310.

2015

Fertigung der ersten Schere mit 250 U/min. zum Zerteilen von Stanzgitter hinter einer Schnellläuferpresse.

2017

Fertigung der ersten Winkelschere zum gleichzeitigen Besäumen zweier Ecken und Seiten von Tiefziehbauteilen.

2017

Erste Feinschnittschere für das automatisierte Schneiden von Epstein-Proben speziell für die Qualitätskontrolle von Elektroblech.

2018

Fertigung der ersten Bandstahlschere zum Zerteilen von Vulkollan und Gummi mit einer Stärke von bis zu 50 mm.

2022

Fertigung der ersten Bandstahlschere zum Zerteilen von Celullolse-Isolationsmaterial für die Transformatorenherstellung.

2022

Automatisierung des Längsteilens von Dachprofilen mit einer Länge von bis zu 7,5 m unter Verwendung einer Schlitzschere.

2023

Bau der ersten Exzenterschere zum verwindungsarmen Schneiden von Titan-Nickel-Kathoden für die Chlorgaselektrolyse.

2023

Bau einer High-End-Stanzgitterschere mit vergrößerter hydraulischer Kupplung bis zu 80 Auslösungen pro Minute bei einer Dauerhubzahl von 140 U/min.

2023

Erweiterung der PV-Anlage auf dem Halledach auf nun ingsesamt 117 kWp für mehr Autarkie und CO²-Einsparung.

2024

Geplanter Bau der ersten Bi-Servoschere als fliegende Schere in einer Laserblanking-Line.

HABEN SIE FRAGEN?

WIR HELFEN GERNE WEITER.

KONTAKT

Wir freuen uns über Ihren Anruf oder Ihre Nachricht.

Haben Sie Fragen zu unseren Produkten oder einen Terminwunsch?

Wir setzen uns gerne mit Ihnen in Verbindung.

| Telefon: +49 7021 59056 |

| E-Mail: info@hsk-maschinen.de |

Bitte beachten Sie vor dem Versand Ihrer Nachricht die Datenschutzerklärung.

Die mit * gekennzeichneten Felder sind Pflichtfelder.