CONTRACT PRODUCTION

//

The main expertise of our contract production team lies in a flexible production of complex components and thereby realizing Your individual requests on a very high technical standard. Our focus lies in the custom-made production of individual parts and small series.

The described travel paths of the machines tell You how big the maximum dimensions of the ordered parts may be.

Welding

Our welding department is equipped with three MAG welders, two arc welders and one welding torch. We can also work on an individually constructed straightener with the table dimensions of: 700 x 2500 mm.

MILLING

- CNC-Milling machine Keckeisen UBF 3500, Control: Heidenhein TNC 415,

Paths: X: 3500 Y: 1000 Z: 1000, A 0 bis -180, B 0 bis -90, maximum load 5t - CNC-Milling machine Maho 2000C, Control: Philips CNC 532,

Paths: X: 1500 Y: 650 Z: 1000 - CNC-Milling machine Maho 1000C, Control: Philips CNC 432,

Paths: X: 1000 Y: 800 Z: 500 - Conventional milling machine Deckel FP3L, Paths: X: 800 Y: 300 Z: 300

- Conventional milling machine Deckel FP3, Paths: X: 500 Y: 300 Z: 300

- Boring Mill PEGARD, Belgien, Paths: X: 1900 Y: 800 Z: 600,

Faceplate D=600, quill D=80, Table dimensions: 850 x 1250

PLANING AND SHAPING

- Two-column planing machine, Reichle und Knödler K3000

Width: 1015 Planing length: 3250 - Shaping, Klopp, stroke: 750, width: 600

- Shaping, Heinemann, stroke: 500 width: 400

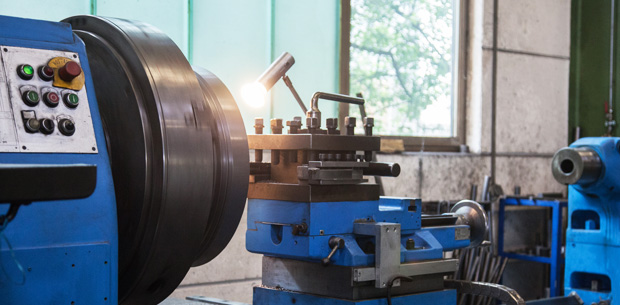

TURNING

- Turning machine Wohlenberg VW 1250, Turning diameter over bed 1230,

Turning length 3000, spindle bore 160 mm - Turning machine Matra MD22S, Turning diameter over bed 440

Turning length 1200, spindle bore 60 mm - Turning machine Uva LZ 40, Turning diameter over bed Bett 400

Turning length 1000, spindle bore 50 mm - Turning machine Weisser G1, Turning diameter over bed 400

Turning length 1300, spindle bore 40 mm - Turning machine Weisser PO2, Turning diameter over bed 300

Turning length 1000, spindle bore 20 mm

SHEET METAL PROCESSING

You can also benefit from our wide experience regarding sheet metal processing. We can cut sheet metal for you to a width of 2500 mm and 15 mm sheet thickness with the guillotine shears in our company. Before a machine order takes place, we are happy to perform cutting tests, with various cutting parameters like cutting thickness, cutting speed and cutting angle. A notching machine as well as a swivel bending machine complete our machine park in the sheet metal processing department.

- Servo- guillotine shears HSK/W 1330 x 1,5, cutting angle 1,3°

- Guillotine shear HSK/S 530 x 10, cutting angle 0° und 2°

- Guillotine shear HSK/S 1030 x 15, cutting angle 3,9°

- Guillotine shear HSK/S 2530 x 4,5, cutting angle 1,75°

- Notching machine Indumasch

- Swivel bending machine FASTI 3000 x 4